3VM52-000-29 可以直接连接到监控系统,或者,如果使用接近发射器直接输入到控制系统。当与监测系统一起使用时,它们是整体振动、间隙电压、1X幅度和相位、2X幅度和相位、nX幅度和相位以及非1X等离散振动参数的极佳来源。这些离散参数对于确定特定故障非常有用。然而,通常情况下,设置这些参数并维护它们以使其具有意义所需的时间和精力并不值得。在大多数情况下,这些参数存在于振动监测系统(VMS)中,但未被使用。通常只使用直接幅度,并将其输入到控制系统,例如振动变送器的输出。

联系人:张工 Simon

联系电话:+8613822101417

电子邮箱:sales@qimingplc.com

服务热线

服务热线

13822101417

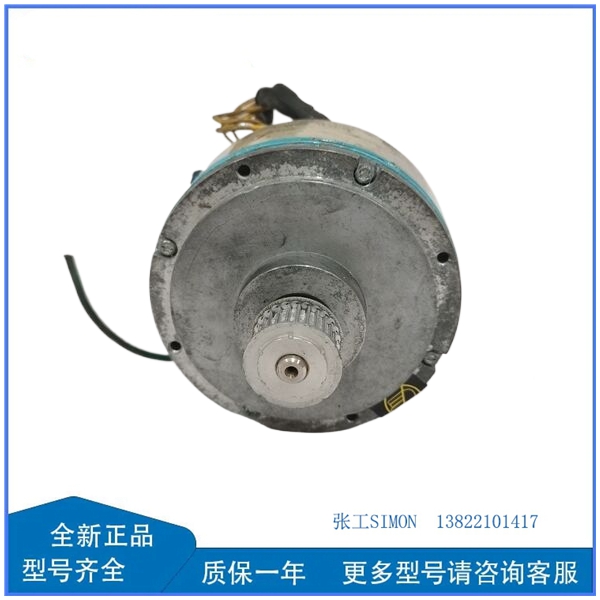

型号:33VM52-000-29

中文产品介绍:

对于33VM52-000-29 ,振动监测解决方案应取决于非计划停机的成本。由关键旋转或往复机器的问题引起的非计划停机是工厂最昂贵的停机时间。工厂因失去利润(失去的盈利机会成本=利润损失)、紧急维修、材料和人工成本、备用人工成本、质量问题是而失去金钱,客户信任/交付问题,最重要的是人员安全问题。应用于机器资产的感官解决方案取决于非计划停机事件的可能性。如果资产停机不对人员、设施或社区构成风险,则振动监测解决方案 minimal。

33VM52-000-29 可以直接连接到监控系统,或者,如果使用接近发射器直接输入到控制系统。当与监测系统一起使用时,它们是整体振动、间隙电压、1X幅度和相位、2X幅度和相位、nX幅度和相位以及非1X等离散振动参数的极佳来源。这些离散参数对于确定特定故障非常有用。然而,通常情况下,设置这些参数并维护它们以使其具有意义所需的时间和精力并不值得。在大多数情况下,这些参数存在于振动监测系统(VMS)中,但未被使用。通常只使用直接幅度,并将其输入到控制系统,例如振动变送器的输出。通常,基于机架的系统的直接幅度被用作振动停机信号。33VM52-000-29 将离散振动参数引入控制系统是不合理的,除非这些参数被维持。因为,在大多数情况下,这些参数不会被维持,所以除非控制系统扫描速率超过0.1秒,将VMS作为控制系统的附加部分引入控制系统是不合理的。扫描周期超过0.1秒的长扫描周期使得将控制系统用作保护系统的效果不很有效。要将控制系统用作保护系统,扫描速率必须小于0.1秒。1秒使控制系统的使用作为保护系统不太有效。33VM52-000-29 要将控制系统用作保护系统,扫描速率必须小于0.1秒。1秒使控制系统的使用作为保护系统不太有效。要将控制系统用作保护系统,扫描速率必须小于0.1秒。

当工业场所的范围、规模和运营各不相同,33VM52-000-29 接近监测为操作员和工程师提供了一种了解最偏远的流体膜轴承机器的方法。接近传感器可以准确捕捉振动水平。

英文产品介绍:

For 33VM52-000-29, the vibration monitoring solution should depend on the cost of unplanned downtime. Unplanned downtime caused by issues with critical rotating or reciprocating machines is the most expensive downtime for factories. The factory loses money due to loss of profit (lost profit opportunity cost=loss of profit), emergency repairs, material and labor costs, backup labor costs, quality issues, customer trust/delivery issues, and most importantly, personnel safety issues. The sensory solutions applied to machine assets depend on the likelihood of unplanned downtime events. If asset downtime does not pose a risk to personnel, facilities, or communities, then vibration monitoring solutions are minimal.

33VM52-000-29 can be directly connected to the monitoring system, or if a proximity transmitter is used, it can be directly input to the control system. When used in conjunction with monitoring systems, they are an excellent source of discrete vibration parameters such as overall vibration, gap voltage, 1X amplitude and phase, 2X amplitude and phase, nX amplitude and phase, and non-1X. These discrete parameters are very useful for determining specific faults. However, in general, the time and effort required to set these parameters and maintain them to make them meaningful is not worth it. In most cases, these parameters exist in vibration monitoring systems (VMS) but are not used. Usually only direct amplitude is used and input into the control system, such as the output of a vibration transmitter. Usually, the direct amplitude of rack based systems is used as a vibration shutdown signal. It is unreasonable to introduce discrete vibration parameters into the control system unless these parameters are maintained. Because in most cases, these parameters are not maintained, it is unreasonable to introduce VMS as an additional part of the control system unless the scanning rate exceeds 0.1 seconds. The long scanning period exceeding 0.1 seconds makes it less effective to use the control system as a protection system. To use the control system as a protection system, the scanning rate must be less than 0.1 seconds. 1 second makes the use of the control system as a protective system less effective. 33VM52-000-29 To use the control system as a protection system, the scanning rate must be less than 0.1 seconds. 1 second makes the use of the control system as a protective system less effective. To use the control system as a protection system, the scanning rate must be less than 0.1 seconds.

When the scope, scale, and operation of industrial sites vary, 33VM52-000-29 proximity monitoring provides operators and engineers with a way to understand the most remote fluid film bearing machines. Proximity sensors can accurately capture vibration levels.

在线留言

ONLINE MESSAGE