IS420ESWBH3A的监测配备了上述相同的特性,这些特性使您能够在正常加工条件下识别出异常趋势,并防止机器故障。您还可以按需进行机器诊断,并使用与工厂过程数据集成的传感器。这是机器振动监测的最高形式。振动监测系统的常见应用,IS420ESWBH3A振动监测系统可以用于各种不同的应用。

联系人:张工 Simon

联系电话:+8613822101417

电子邮箱:sales@qimingplc.com

服务热线

服务热线

13822101417

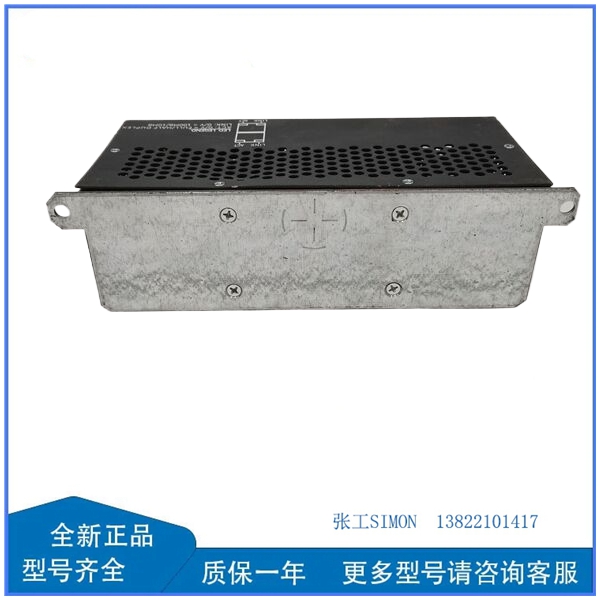

型号:IS420ESWBH3A

中文产品介绍:

IS420ESWBH3A的监测配备了上述相同的特性,这些特性使您能够在正常加工条件下识别出异常趋势,并防止机器故障。您还可以按需进行机器诊断,并使用与工厂过程数据集成的传感器。这是机器振动监测的最高形式。

振动监测系统的常见应用

IS420ESWBH3A振动监测系统可以用于各种不同的应用。以下是一些最常见的工业用途:

需要注意的是,旋转或往复机器上使用的振动传感器数量取决于设备的重要性。对于那些如果停机一天就会造成超过10万美元损失的关键设备,每个径向轴承、推力传感器和相位触发器至少需要安装XY振动传感器。如果机器不太关键,每天的损失不到10000美元,可能只需在最靠近联轴器的负载侧轴承上安装一个振动传感器就足够了。在这两个极端之间,需要根据具体情况判断如何最佳地监控机器,以便工厂能够获得投资回报(ROI),这可能是一个或两个具有开关功能(警报/停机)的传感器。

1. 旋转机械

IS420ESWBH3A旋转设备和机械,如电机、风扇、涡轮机和变速箱,是您会发现振动监测系统最常见的一些地方。由于多个不同的旋转部件同时旋转并产生其振动模式,振动监测对于确保所有组件正常工作至关重要。对于旋转设备,一个问题是可能导致设备损坏和灾难性故障。振动监测可以帮助识别旋转机械中的不对中、不平衡、摩擦、轴承故障或甚至是共振问题。

2. 轴承和齿轮

在机器的轴承和齿轮中,各种振动以不同的频率发生,这就是为什么振动监测系统如此常见的原因。对于齿轮而言,当设备执行其预期任务时,会产生多种不同的振动模式。这些不同的振动对于人类来说单独监测是非常困难的,因此采用监测系统进行早期预警对机器的持续功能至关重要。

3. 往复式压缩机、发动机和泵

IS420ESWBH3A往复式压缩机、发动机和正位移泵等设备内部都有多个正在振动的部件。往复式机械的独特之处在于其零件同时以旋转和线性运动的方式移动。监测这些不同零件的振动可以帮助在它们造成机器损坏之前识别潜在的故障。

4. 桥梁

在确保桥梁结构安全时,振动监测至关重要。振动趋势可以帮助建立一个桥梁在未受损和健康状态下的基准线,然后检测是否可能遇到结构问题。如果桥梁开始显示出异常的振动行为,维护人员可以进行必要的检查以确定问题的来源。

英文产品介绍:

The monitoring of IS420ESWBH3A is equipped with the same features mentioned above, which enable you to identify abnormal trends under normal processing conditions and prevent machine failures. You can also perform machine diagnostics as needed and use sensors integrated with factory process data. This is the highest form of machine vibration monitoring.

Common Applications of Vibration Monitoring Systems

The IS420ESWBH3A vibration monitoring system can be used for various applications. Here are some of the most common industrial uses:

It should be noted that the number of vibration sensors used on rotating or reciprocating machines depends on the importance of the equipment. For critical equipment that would cause losses exceeding $100000 if shut down for a day, each radial bearing, thrust sensor, and phase trigger needs to be equipped with at least XY vibration sensors. If the machine is not critical and the daily loss is less than $10000, it may be sufficient to install a vibration sensor on the load side bearing closest to the coupling. Between these two extremes, it is necessary to determine how to best monitor the machines based on specific circumstances, so that the factory can achieve a return on investment (ROI), which may be one or two sensors with switch functions (alarm/shutdown).

1. Rotating machinery

IS420ESWBH3A Rotating equipment and machinery, such as motors, fans, turbines, and gearboxes, are some of the most common places where you will find vibration monitoring systems. Due to the simultaneous rotation of multiple different rotating components and the generation of their vibration patterns, vibration monitoring is crucial to ensure the proper functioning of all components. For rotating equipment, one issue is the possibility of equipment damage and catastrophic failure. Vibration monitoring can help identify misalignment, imbalance, friction, bearing failures, or even resonance issues in rotating machinery.

2. Bearings and gears

In the bearings and gears of machines, various vibrations occur at different frequencies, which is why vibration monitoring systems are so common. For gears, various vibration modes are generated when the equipment performs its expected tasks. It is very difficult for humans to monitor these different vibrations separately, so using a monitoring system for early warning is crucial for the continuous function of the machine.

3. Reciprocating compressors, engines, and pumps

There are multiple vibrating components inside equipment such as IS420ESWBH3A reciprocating compressors, engines, and positive displacement pumps. The unique feature of reciprocating machinery is that its parts move in both rotational and linear motion simultaneously. Monitoring the vibration of these different parts can help identify potential faults before they cause machine damage.

4. Bridges

Vibration monitoring is crucial in ensuring the safety of bridge structures. Vibration trends can help establish a baseline for a bridge in an undamaged and healthy state, and then detect potential structural issues. If the bridge begins to exhibit abnormal vibration behavior, maintenance personnel can conduct necessary inspections to determine the source of the problem.

在线留言

ONLINE MESSAGE